Why do mullions cause problems for window manufacturers and door prehangers? Well, NAFS testing would be a lot simpler without them. Most Canadian manufactures used to test one fixed window, one casement, one awning, and one slider from each product line and their testing was done. That was before NAFS, when testing to CAN/CSA A440-00 for windows and CAN/CGSB-82.1-M89 for sliding doors were the only fenestration standards the window industry had to deal with. Few were testing skylights, and no one was testing side hinged doors.

Of course, that wasn’t the intent of the old standards. Mullions weren’t supposed to be ignored. But they were. Manufacturers, test labs, and Canadian certifying organizations generally didn’t look too closely into the mullion testing requirements of older Canadian test standards. Perhaps the requirement to test the sizes and configurations manufacturers were actually building were just not spelled out clearly enough.

So What Changed?

Two things. First, the Canadian Standards Association released the 2008 edition of its fenestration testing standard, A440-08, which in the years since the 2000 edition had been harmonized with American standards and was now known as the North American Fenestration Standard, or NAFS.

Next came the 2010 National Building Code of Canada, which required manufacturers to comply with NAFS – a standard that now covered not only windows, but also sliding doors, side hinged doors and skylights. NAFS made it clear that performance ratings on product labels had to be based on testing of product configurations and sizes at least as large as those labeled.

NAFS and Mullions

The NAFS standard is very clear that the performance ratings of products with mullions must be based on the testing of products with mullions.

Why is this important? Because mullions are structurally the weakest members of window and door frames. Unlike the perimeter frame which is attached on all sides to the wall, mullions are supported only at the ends. They also offer additional paths for air leakage and water infiltration. The performance ratings of products with mullions are typically much lower than the ratings of individual units.

Two Kinds of Mullions, Two Types of Product

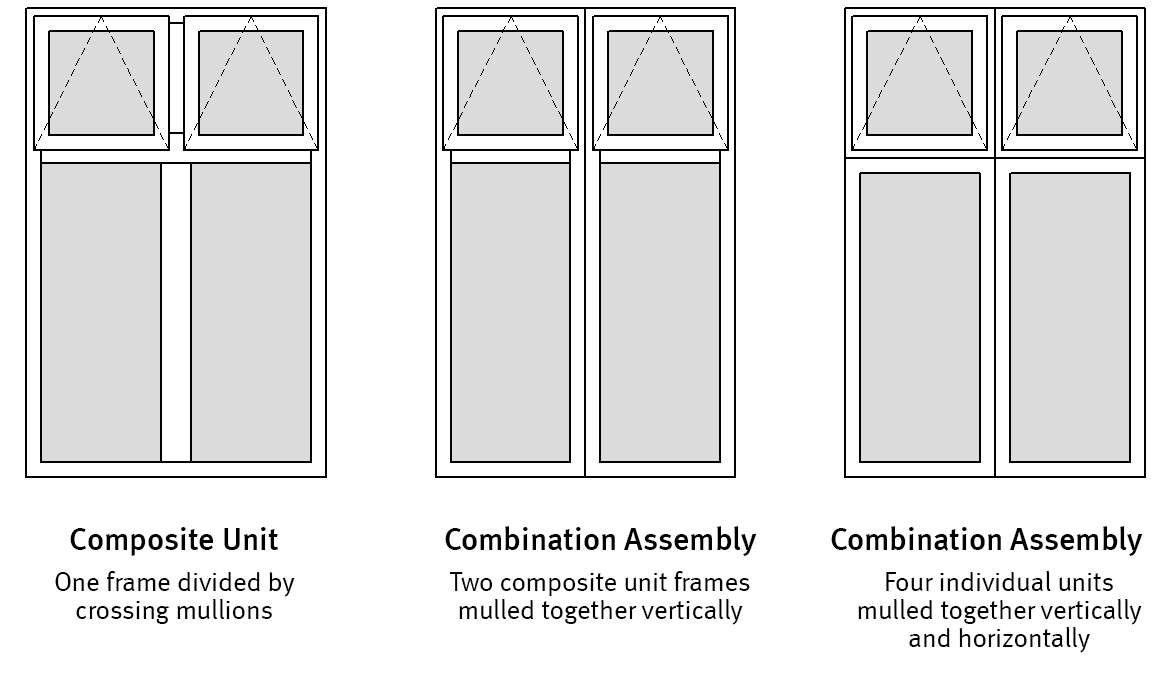

Not all mullions are the same. NAFS distinguishes two different kinds of mullions: integral mullions are bounded at either end or both ends by crossing frame members, and combination mullions are formed by joining two or more individual unit frames together. The mullions in turn define two types of products: composite units and combination assemblies. The testing and labeling options for these two kinds of products are different.

Consider the three windows illustrated below. While they look awfully similar to one another, they are constructed very differently. The composite unit on the left is constructed as a single window. First the perimeter (outer) frame is assembled, then a horizontal mullion is installed, followed by the two vertical mullions, one above and one below the horizontal mullion. The mullions in a composite unit are made of one piece and are called integral mullions. In a composite unit all framing members must be assembled together before glass can be installed.

The window on the right is composed of four separate individual unit windows: two top hinged awning windows above, and two fixed (non-operable) windows below. That is why it is called a combination assembly: it is assembled by combining individual units together, and where the adjoining frames connect, they create combination mullions. In many cases the individual units are glazed and completely finished before they are assembled into a larger window.

The window in the middle is also a combination assembly, but is composed of two composite units, each of which has a horizontal mullion dividing the fixed lite below from the awning sash above.

Mullions, Testing and Labeling

With several kinds of mullions to deal with, NAFS testing can get pretty complicated. Consider the three window examples above. To consumers, all three windows look the same. But to NAFS, to a test lab, and to an engineer, these are fundamentally different products. The structural load paths in each of these three windows is different, and testing will likely show that these three windows have different structural, airtightness, and water penetration resistance ratings.

A manufacturer offering each of these window types will have to test each of them to determine their ratings. If the manufacturer also has reinforcing options for each of these window types, the reinforced windows also need to be tested. So to rate the performance of one style of window could require multiple expensive lab tests, as well as multiple labels with different ratings for the various options. Confusing? You bet.

The requirement to test products with mullions significantly increases the amount of testing manufacturers must perform, and adds great complexity to product labeling.

No surprise then that as NAFS enforcement picks up in jurisdictions across Canada, many manufacturers are seeking relief from onerous testing and labeling requirements.

What about Doors?

Does any of this apply to doors? The answer is: yes. Mullion testing and rating requirements apply equally to side hinged and sliding doors when they include mullions and transoms, as in the image below.

Photos courtesy of Lux Windows and Glass Ltd.

New Guidelines Clear up the Confusion

To clear up the confusion and to help manufacturers, test labs and certification agencies in Canada and the U.S. work within a uniform framework, Fenestration Canada commissioned a committee with representatives from both Canada and the U.S. to address Canadian mullion testing and labeling requirements. The committee also identified resources referenced within the NAFS standard that allow the use of testing-based engineering methods that can be used to reduce the amount of physical testing required to obtain valid NAFS performance ratings for mulled products.

The committee’s work resulted in the publication of two important documents in September 2014, available at no charge in English and French, on the Fenestration Canada website:

- Voluntary NAFS Labeling Guidelines for Products with Mullions

- Recommendation on the Use of Engineering Calculations to Determine Design Pressure Ratings of Fenestration Products under NAFS‐08

You can learn more about these important documents in my comprehensive article published in the Fall 2013 edition of Fenestration Review. View or download the article as a PDF file.

Summary of Canadian NAFS Labeling Guidelines and Resources

For convenience, links to documents and articles mentioned in this post are summarized below:

- NAFS labeling guidelines for Canada

- Voluntary NAFS Labeling Guidelines for Products with Mullions

- Recommendation on the Use of Engineering Calculations to Determine Design Pressure Ratings of Fenestration Products under NAFS‐08

- “Mullions and NAFS” article in Fall 2014 edition of Fenestration Review. Read online or download as PDF file.