At RDH, we are always looking for new ways to add value for our clients—and ultimately, to make buildings better. To this end, we are happy to announce that we have added Electronic Leak Detection (ELD) to our long list of capabilities. We can conduct ELD testing to both existing and new building projects depending on your project’s needs. If you are not familiar with ELD, keep reading to find the answers to these questions:

- What is Electronic Leak Detection?

- What are the advantages of ELD?

- Who is using ELD?

- Why is RDH best positioned to offer ELD?

If you would like to learn about ELD or how RDH can help you on your project, please contact Kyle Silliker, ksilliker@rdh.com.

What is Electronic Leak Detection?

Originating in Europe, ELD is a non-destructive method to find breaches or punctures in roof and waterproofing membranes—which is very helpful for forensics/leak investigations and quality assurance purposes. ELD has become a prominent method of verifying that waterproofing and roofing membranes are watertight and has largely overtaken flood testing as the preferred method across the US and Canada. With advancements in both technology and industry best practices, ELD has gained popularity due to its ability to provide accurate results at a low cost. ELD is available in low-voltage and high-voltage testing. Low-voltage testing is most common because it can be performed year-round, while high-voltage testing is better suited for testing dry-membranes. Both methods work by creating two electrical plates between the nonconductive roof membrane and the grounded conductive building enclosure component.

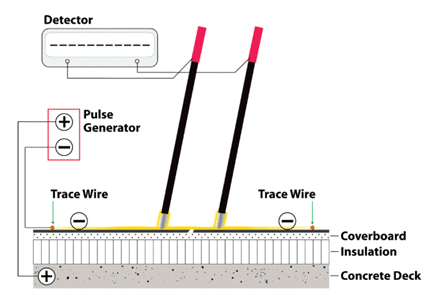

To conduct an ELD test, a technician places a trace wire on the roof membrane and applies water to create an electrical plate above the membrane. A pulse generator is connected to the conductive substrate or conductive layer built into the roof assembly to create the second plate below the membrane. When the pulse generator is connected to the trace wire on top of the membrane and the conductive substrate or conductive layer below the membrane, two directional poles are used to uncover leaks. When a leak is present, the water creates an electrical connection to the building enclosure, and a detector pinpoints the exact leak location to the technician.

ELD testing diagram

Advantages over Flood Testing

ELD provides several advantages over traditional flood testing.

- ELD’s ease of setup means that it is a much more budget- and schedule-friendly method of leak investigation. Execution is much more efficient and allows other trades to continue their work around the testing.

- In comparison to flood testing, ELD poses almost no risk of causing damage to the building enclosure or other systems. The emphasis is on finding and providing solutions to issues, not creating more.

- Using ELD provides an assurance of accuracy because it immediately and accurately locates pinholes so repairs can be completed quickly. The technology used in LED is trusted and tried and minimizes the chance of missing a leak or ingress which cause issues later on.

ELD testing is able to locate damage hidden from the naked eye and pinpoint breach locations.

Who is using ELD?

The practice of ELD has been adopted by building owners, manufacturers, specifiers, consultants, architects, developers, roofers, and general contractors. One reason for this widespread adoption is because of its versatility: ELD can be used on waterproofing membranes installed in roofs, plaza decks, pools, and other waterproofing applications. In the final stages of the construction phase of a new development, ELD is often used to detect any leaks before warranties expire as well as to review overburdened areas, such as green roofs. During the various stages of a building’s life cycle, owners can benefit from ELD’s ability to provide continuous and timely monitoring of membrane performance. Contractors may find this service particularly appealing when they are on a tight schedule and need to confirm an assembly is watertight prior to placing an overburden area.

Small breaches that may otherwise go unnoticed will be discovered.

Why RDH is best positioned to offer ELD?

Helping owners maintain, repair, and renew their buildings has been a core part of RDH’s business since our beginning. Over time, we have successfully used our experience on existing buildings to design and construct better enclosures for new developments and to pioneer key technical innovations. By adding ELD to our list of capabilities, we are able to provide quick, accurate, low-cost leak detection, keeping our clients’ projects moving forward.

Our diverse team of technologists, engineers, architects, and other building professionals can not only conduct ELD, but they can help you understand what the results mean in the context of the entire building enclosure system.

In conjunction with our enclosure consulting services, RDH can apply ELD testing to a range of roof types, including hot rubber, TPO, PVC, BUR, and green roofs. We can also test traffic coatings on interior spaces such as commercial kitchen floors and bathrooms. We are currently providing ELD in Washington, Oregon, and California with the intent of offering ELD in Canada soon.

RDH can offer a range of building enclosure consulting services in conjunction with conducting ELD testing.

If you are interested in learning more about the benefits of ELD or would like to know how it can be applied to your project, please reach out to Kyle Silliker, ksilliker@rdh.com.