![]()

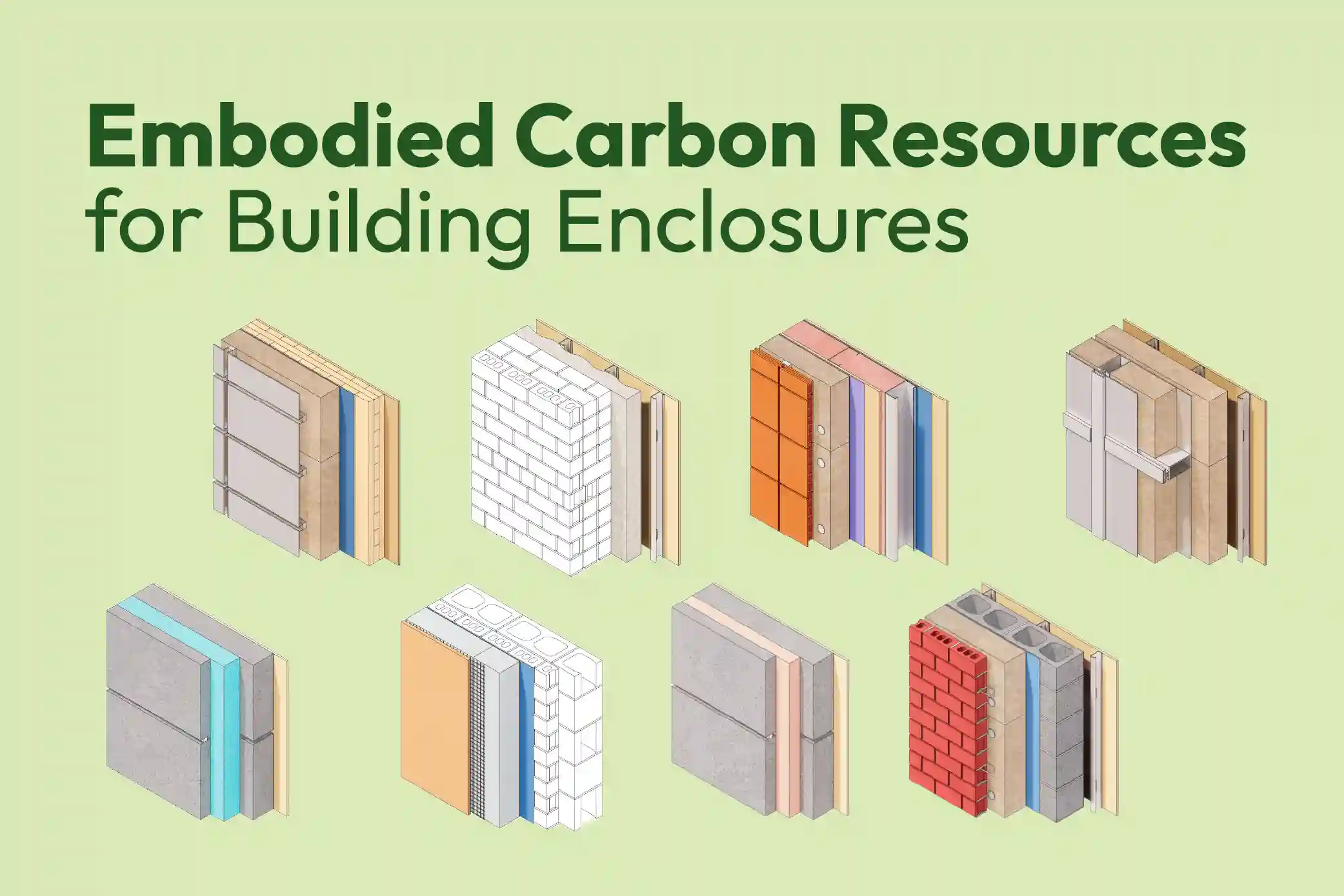

This Toronto Metropolitan University (TMU) x RDH study and resulting database—funded by The Atmospheric Fund (TAF)— inform design decisions at the earliest stages (before details are established) with critical consideration of embodied carbon. Readily available comparative data from studies on assemblies such as this opens up the opportunity to reconsider how materiality can significantly reduce embodied carbon emissions in buildings.

Background

The AEC industry is at an inflection point. A significant portion of a building’s embodied carbon emissions occurs before and during its construction, while the operational emissions from a building’s energy use are drawn out throughout the building’s lifespan. Because embodied carbon emissions happen up front, this means that reducing embodied carbon is even more crucial to achieving near-term emissions reduction goals.

Our collective effort to bring this information to the fore serves designers and manufacturers as they make considered and thoughtful decisions on their building enclosure systems.

TMU x RDH also sees this comparative data as a resource for policymakers to right-size mandates, alternatives, and incentives.

Embodied carbon emissions refer to the amount of GHG emissions associated with upstream stages of a product’s life, i.e., raw material extraction, processing, transportation, and manufacturing. These emissions are not well understood yet contribute significantly to the total carbon emissions produced over a building’s lifespan.

The Study and Outcome

Embodied carbon metrics for twenty-six (26) enclosure systems commonly used in the Greater Toronto and Hamilton Area (GHTA) were analysed using a standardized life cycle assessment methodology for calculating CO2 equivalent embodied emissions.

The results break down emissions by material layer, showing which components have the most negative impact (and where opportunities to reconsider material choice are available).

This comparative data can be used to inform decisions during concept design, before project specifications and detailed drawings are developed and priced, enabling project and team efficiency, productivity, and streamlining.

For more detailed information about this initiative, download our Guidance Document.