Preventing water infiltration requires knowledge of material properties, compatibility, and installation techniques. Establishing and verifying such techniques is a key step in achieving the intended product performance.

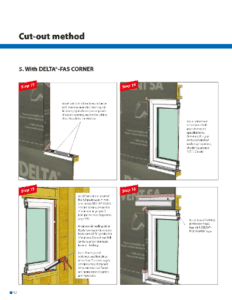

Results from laboratory and field exposure testing confirmed material compatibility within the product line and informed the development of several alternate rough opening preparation details. Alternate configurations included flanged and non-flanged windows, pre-strip versus cut-out installation, and four sill conditions (a flat sill, a sloped sill, a backdam, and a design using DELTA® corner-reinforcing products). A mock-up of each detail was assembled and documented. Once the windows were installed, air and watertightness testing was conducted at RDH’s window testing facility.

Upon successful completion of the tests, the team at RDH created 3-D models of the details to illustrate the step-by-step installation process. Finally, we provided hands-on training to Dörken technical and sales staff to ensure they were prepared to discuss the best practice techniques that were determined.

WATCH:

- DELTA®-VENT SA – Window Installation Details: Strip-in Method, Non-Flanged (Rebate) Window

- DELTA®-VENT SA – Window Installation Details: Cut-out Method, Flanged Window

- DELTA®-VENT SA – Window Installation Details: Strip-in Method, Non-Flanged (Rebate) Frame

- DELTA®-VENT SA – Window Installation Details: Cut-out Method, Flanged Frame

READ:

- Installation Guide: DELTA-VENT SA Flashing Systems for Non-Flanged (Rebate) Windows

- Installation Guide: DELTA-VENT SA Flashing Systems for Flanged Windows

Share This Post

Date:

September 27, 2021

Client:

Dörken Systems Inc.

Project Completed:

2015