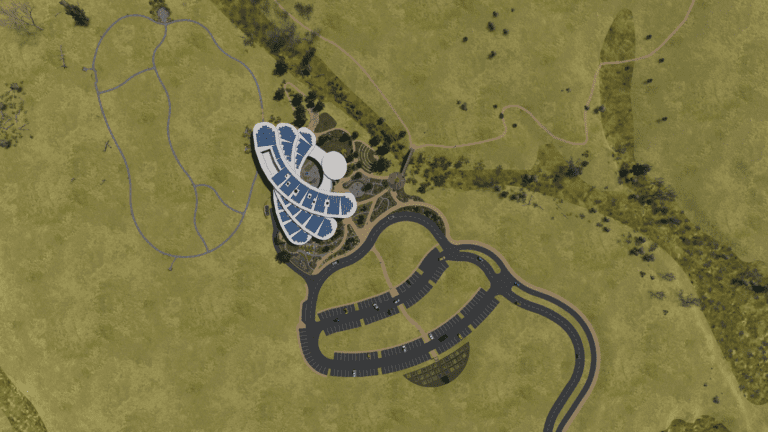

Anythink Nature Library

In partnership with the City of Thornton, the visionary Anythink Nature Library aims to provide...

Read MoreThe Loop Apartments

The Loop Apartments will provide 195 multi-family units across 2 four-story buildings with 2 levels...

Read MoreNorthlake Commons

Northlake Commons is a multi-use development that infuses mass timber and modern amenities, providing more...

Read MoreOld Crowe Health & Wellness Centre

RDH provided comprehensive building enclosure consulting for two completed facilities: a single-storey, 950 m2 Health...

Read MoreAinsworth & Dunn

A historic 1902 Seattle waterfront building that began its service as a salmon-processing warehouse—and more...

Read MoreAmerican River College STEM Building

In fall 2018, the American River College in Sacramento, California, broke ground on a new...

Read MoreCatalyst Building

Standing at five stories tall, the Catalyst Building is the first commercial building in Washington...

Read MoreUniversity of Washington Hans Rosling Center for Population Health

The Hans Rosling Center for Population Health is a symbol of the University of Washington’s...

Read MoreRamona Apartments

Built in 2011, the Ramona Apartments are a short distance from the Willamette River in Portland’s lively Northwest District. The brick veneer, wood-framed building contains 138 affordable,...

Read More1020 Legacy Way

As housing costs continue to increase in the popular resort town of Whistler, BC, locals...

Read More